-

-

FIXED SHADE SAILS

-

ROLL-UP SHADE SAILS

-

OUTLET & ACCESSORIES

-

SAILS BY SHAPE

-

BUYING GUIDE

-

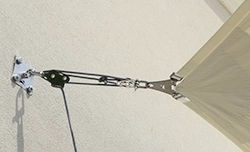

INSTALLATION GUIDE

-

APPLICATIONS

-

-

-

BUYING GUIDE

-

-

CUSTOM ROLLER SHADES

-

STANDARD ROLLER SHADES

-

BUYING GUIDE

-

-

-

-

-

-

Shade sails

-

-

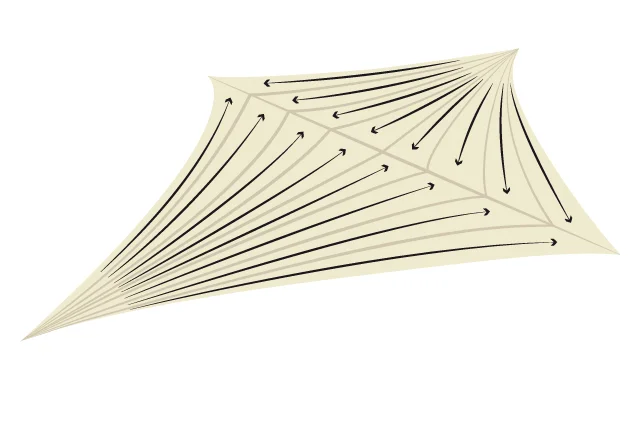

The radial cut

The radial cut is certainly a much more laborious cut that involves working through many cuts: however, it will be this richness to allow a correct and uniform distribution of the tension on the surface of the sail.

English GB (English)

English GB (English)